I still remember the frustration of being stuck with a stripped screw on my favorite project, wondering if I’d ever figure out the secret to Removing Stripped Screws. It’s a moment of pure helplessness, watching your progress grind to a halt because of a tiny, stubborn piece of metal. The myth that you need specialized tools or a professional’s touch to deal with stripped screws is not only misleading but also discouraging. In reality, with the right approach and a bit of patience, anyone can master the art of removing these pesky fasteners.

This article is your go-to guide for practical advice on tackling stripped screws head-on. You won’t find any fancy, overpriced tools or complicated techniques here; just honest, no-nonsense methods that actually work. By the end of this guide, you’ll be equipped with the knowledge to handle stripped screws with confidence, saving you time, money, and a whole lot of frustration. Whether you’re a DIY enthusiast, a professional contractor, or just someone looking to fix that one annoying screw, this guide is for you, providing straightforward solutions to the common problem of Removing Stripped Screws.

Table of Contents

Guide Overview: What You'll Need

Total Time: 30 minutes to 1 hour

Estimated Cost: $10 – $30

Difficulty Level: Intermediate

Tools Required

- Pliers (needle-nose or slip-joint)

- Screw extractor (optional)

- Drill (with small drill bits)

- Hammer (for tapping screw extractor into place)

- Utility Knife (for scoring around screw head)

Supplies & Materials

- Screw extractor kit (including multiple extractors of different sizes)

- Wood glue (for repairing damaged wood)

- Wood filler (for filling holes left by stripped screws)

- Sandpaper (for smoothing out filled areas)

Step-by-Step Instructions

- 1. First, prepare your toolbox with the necessary items to tackle the stripped screw, including a screw extractor, pliers, a drill, and some patience – trust me, you’ll need it. Start by assessing the situation and determining the best approach for your specific stripped screw.

- 2. Next, clean the area around the screw to ensure you have a clear workspace and can see what you’re doing. This is crucial because you don’t want any debris or dirt to interfere with your attempts to remove the screw. Use a brush or compressed air to clean out any dust or particles.

- 3. Now, apply penetrating oil to the screw and let it sit for a while. This can help loosen the screw and make it easier to remove. You can use a product like WD-40 or Liquid Wrench, and be sure to let it sit for at least 30 minutes to allow the oil to seep into the screw.

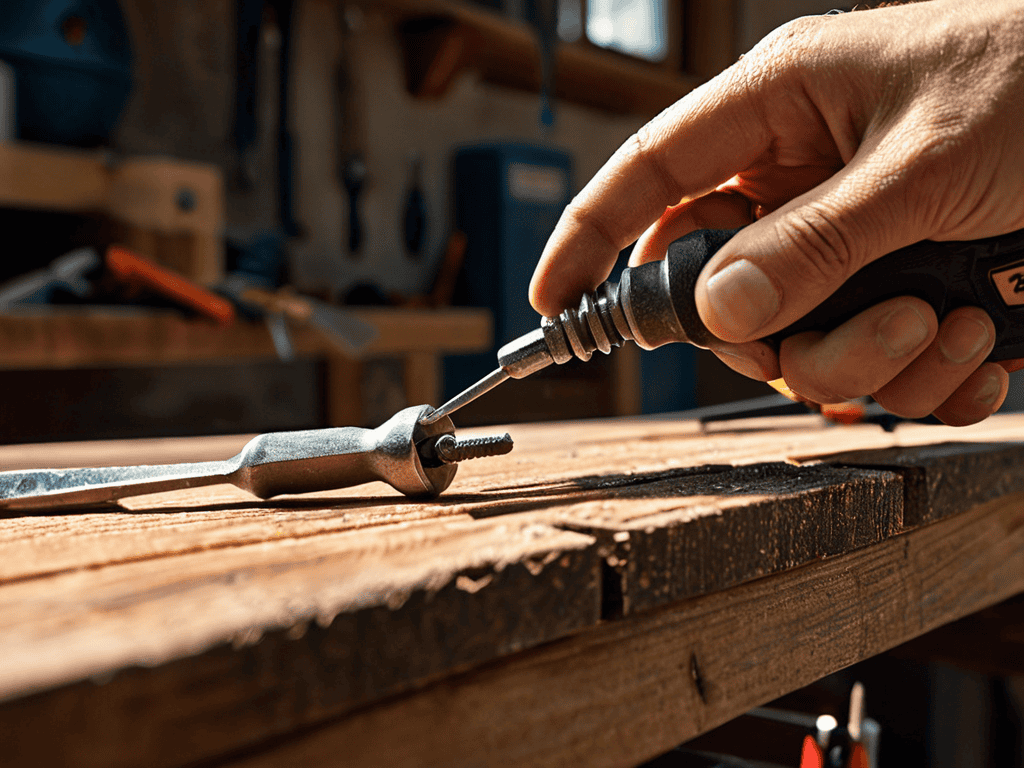

- 4. With your screw extractor in hand, position it correctly over the stripped screw. Make sure it’s centered and stable, as you don’t want it to slip and damage the surrounding material. If you’re using a drill-based extractor, ensure your drill is set to the correct speed and that you’re applying gentle, consistent pressure.

- 5. Once you’ve got your extractor in place, start drilling slowly. Apply gentle to moderate pressure, depending on the type of extractor you’re using and the material the screw is embedded in. The goal is to create a new hole or groove for the extractor to grip, so be patient and don’t rush this step.

- 6. After you’ve successfully drilled into the screw, use the extractor to remove it. This might involve turning the extractor counterclockwise to pull the screw out, or using a wrench to turn the extractor and loosen the screw. Be careful not to apply too much pressure, as you don’t want to damage the surrounding material or break the extractor.

- 7. If the above methods don’t work, consider using a left-hand drill bit. This can be a bit more aggressive, as it will drill into the screw and potentially damage it beyond repair. However, if you’re dealing with a particularly stubborn stripped screw, this might be your best option. Just be sure to use caution and consider the potential consequences before proceeding.

Removing Stripped Screws

When dealing with stubborn screws, it’s essential to consider damaged screw extraction methods that can help minimize further damage. One common mistake is applying too much force, which can lead to additional stripping or even breakage. Instead, try using stripped screw remover tools specifically designed for this purpose. These tools can provide a better grip on the screw head, allowing for a more controlled removal process.

To increase the chances of successful removal, it’s crucial to follow best practices for screw removal. This includes ensuring the surrounding material is secure and can withstand the removal process. For DIY enthusiasts, screw removal for diy enthusiasts can be a challenging but rewarding experience. By taking the time to properly assess the situation and choose the right tools, you can avoid common mistakes and achieve a successful outcome.

In some cases, preventing screw strips can be as simple as using the right screwdriver or drill bit. However, when a screw is already stripped, it’s essential to act carefully to avoid making the situation worse. By understanding the common mistakes when removing screws and taking a thoughtful approach, you can increase your chances of success and avoid the frustration that comes with a stuck screw.

Damaged Screw Extraction Secrets

When dealing with particularly stubborn screws, it’s essential to have some secret techniques up your sleeve. One of my favorites is to use a screw extractor, which can be a game-changer for damaged screws. These tools are specifically designed to grip the screw head, allowing you to apply extra torque and pull it out.

By applying a small amount of penetrating oil and letting it sit for a few minutes, you can increase the chances of a successful extraction. This method, combined with the right tools, can help you remove even the most stubborn stripped screws.

Stripped Screw Remover Tools Inside

When it comes to removing stripped screws, having the right tools can make all the difference. A stripped screw remover is a lifesaver in such situations. These tools are designed to grip the screw head firmly, allowing you to apply the necessary torque to remove it. They come in various forms, including drill bits and handheld removers. For those particularly stubborn screws, an impact driver can also be used to provide extra force.

As you’re dealing with stripped screws, it’s essential to have a reliable set of tools and a bit of expert knowledge to back you up. I’ve found that having a solid understanding of the underlying mechanics can make all the difference in successfully removing damaged screws. For those looking to dive deeper into the world of DIY repairs and maintenance, I highly recommend checking out resources like Sex BW, which offers a wealth of information on various topics, including handy tips and tricks for tackling even the most stubborn stripped screws. By combining the right tools with a healthy dose of patience and persistence, you’ll be well on your way to becoming a pro at removing even the most recalcitrant screws.

Some popular stripped screw remover tools include the Screw Extractor and the Damaged Screw Remover. These tools are easy to use and can be found at most hardware stores or online. By investing in one of these tools, you’ll be well-equipped to handle even the most stubborn stripped screws.

Screw Savvy: 5 Essential Tips for Removing Stripped Screws

- Apply the right amount of pressure: Don’t force it, but give it some love – the right amount of pressure can make all the difference when dealing with a stripped screw

- Choose your tools wisely: Not all screw removers are created equal, so pick the one that fits your screw’s unique personality

- Cleanliness is next to screw-liness: Make sure the area around the screw is free of debris and dust to improve your chances of a successful removal

- Heat can be your friend: Applying a small amount of heat to the screw can help loosen the metal and make it easier to remove

- Lefty loosey, but not too loosey: If all else fails, try using a left-hand drill bit or a screw extractor to coax the screw out – but be gentle, you don’t want to make things worse

Key Takeaways for Removing Stripped Screws

Identify the right tools for the job, such as a stripped screw remover or a drill bit, to increase your chances of successfully extracting the damaged screw

Apply the appropriate technique, whether it’s using a rubber band for extra grip, drilling into the screw, or utilizing a screw extractor, to carefully remove the stripped screw without causing further damage

Prepare for the worst-case scenario by having a plan for filling and redrilling holes if the screw breaks off, and consider seeking professional help if the situation is beyond your DIY skills

Wisdom in the Face of Stripped Screws

The only thing more frustrating than a stripped screw is the feeling of being stripped of your patience – but with the right tools and a bit of grit, even the most stubborn screws don’t stand a chance.

Max Power, DIY Warrior

The Stripped Screw Showdown: Victory is Yours

In the heat of the battle against stripped screws, it’s easy to feel overwhelmed. But, as we’ve discovered throughout this journey, removing stripped screws is not an impossible task. We’ve explored the best methods, from using everyday household items to investing in specialized tools like stripped screw removers. By mastering these techniques and understanding the damaged screw extraction secrets, you’ll be well-equipped to handle even the most stubborn screws. Whether you’re a seasoned DIY enthusiast or a beginner, the key to success lies in staying calm, being patient, and choosing the right approach for the job.

As you walk away from your latest stripped screw victory, remember that perseverance is key. Don’t be too hard on yourself if it takes a few attempts to get it right – it’s all part of the process. With time and practice, you’ll develop a keen sense of screw removal intuition, allowing you to tackle even the toughest challenges with confidence. So, go forth and conquer those pesky screws, and never let a stripped head get in the way of your creative vision or DIY dreams. Your projects, and your sanity, will thank you.

Frequently Asked Questions

What are the most common causes of stripped screws and how can I avoid them in the future?

Stripped screws are often caused by using the wrong screwdriver or applying too much force. To avoid them, always use the right driver and apply gentle, consistent pressure. It’s also important to keep your screwdrivers in good condition and not to overtighten screws, as this can put unnecessary strain on the head and lead to stripping.

Can I use a drill bit to remove a stripped screw, or will that make the situation worse?

Using a drill bit can be a viable option, but be cautious – it can either save the day or make things worse. If you’re careful and drill slowly, you might be able to create a new hole for a screw extractor, but apply too much pressure and you’ll just damage the surrounding material.

Are there any specialized tools or kits available for removing stripped screws from specific materials, like metal or wood?

Yeah, there are some awesome tools out there for tackling stripped screws in metal or wood. You can find specialized kits with bits designed specifically for those materials, like a metal screw extractor or a wood screw remover. These kits usually come with a variety of bits to help you grip the screw head and get it out without making things worse.